Quality Control of IML Packaging

Control of buckets, lids and containers

Control of buckets, lids and containers

In the in-mold labeling (IML) process, the label is placed in a mold and liquid plastic is injected. The result is a product in which label and product are permanently bonded.

In-mold labeling is used for a wide variety of food packaging, such as yogurt, ice cream or cream cheese, but also for paint buckets or detergent bottles.

Thanks to many years of experience in the quality control of IML products, mevisco camera systems are optimally adapted to the needs of IML production.

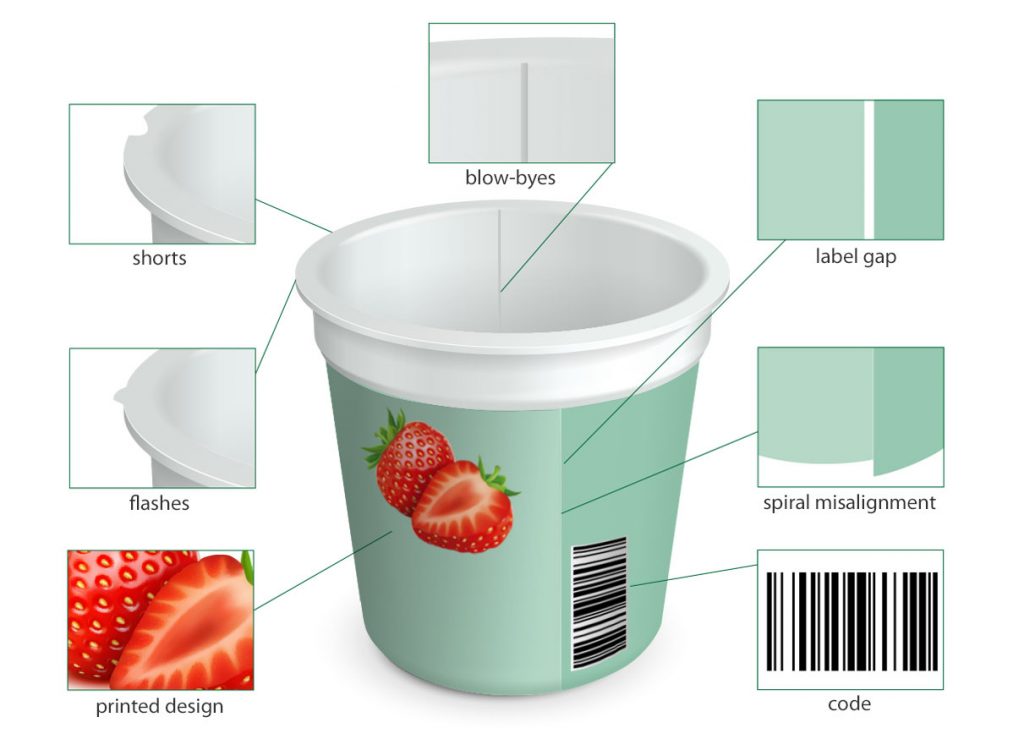

IML inspection criteria on the example of a yoghurt cup packaging.

In the IML injection molding process, overmolding (flashes), undermolding (shorts) and blow-byes can occur. Our image processing systems reliably detect these defects. At the same time, the label position and features of the label design can be checked.

By using an automatic quality control system, defect-free product quality can be guaranteed.

In addition, a vision system can increase the performance of the production line. Problems in the production process are detected by the vision system during production, and personnel or higher-level systems are notified. This allows an immediate response to production problems and increases the performance of the production line.

Fast handling systems are often used in IML production. Our systems use extremely high-intensity lighting we developed. This allows movement speeds of more than 8m/s to be realized.

The evaluation of the camera images is done on powerful industrial computers to provide the results in time.

We adapt to your cycle time and not vice versa!

IML products often use hundreds of different labels. With our systems, a new label can be taught in a few minutes via auto-teach based on an existing label.

If you want to load a label that has already been set up, you only need two clicks.

Our systems can store thousands of different label types.

Our systems generate production statistics per inspection criterion and cavity. This allows production problems to be identified down to the cavity.

You can either use the statistics within our image processing software mips or access the production data via a web interface from anywhere within your company.

Light, dark or transparent labels often require different lighting scenarios. We create the appropriate lighting scenario for different label types.

If different label variants are running on a machine, the appropriate lighting scenario is loaded automatically when the type is loaded.

In addition to production quality, our camera systems can be used to check the label type. The inspection can be carried out via an applied code or via the printed design itself. The uniqueness of the printed design is difficult to guarantee for a large number of varieties, and barcodes are not available everywhere and are often ambiguous.

Our systems can also recognize different varieties via a Digimarc watermark. The design of the packaging is enhanced by Digimarc watermarks. This extension is not perceptible to the human eye and can be used like a barcode.

Digimarc watermarks are a central part of the Holy Grail 2.0 initiative, which aims to optimize the recycling of packaging.